Health Care

As the leading manufacturer of carbomer and polyacrylic acid products, We, Anhui Newman Chemicals business and technical team partners with customers to speed innovative health care field to market. Our Neman carbomer products as high-performance excipients, are used in a wide range of applications including health care products, semisolid and liquid formulations, oral care products.

Pharmaceuticals

As the top leading manufacturer of carbomer products, Newman carbomer products are popular and applied in pharmaceutical products as rheology modifiers, tablet binders, suspension stabilizers, extended-release polymers, mucoadhesive aids, and bioavailability enhancers, NM-Carbomer products are well known for their versatility and ease of use as pharmaceutical excipients.

Tab1 NM-Carbomer products application in pharmaceuticals

Pharmaceutical related products

Oral care

Pharmaceutical grade NM-Carbomer products as excipients have been applied in oral care products, here is carbomer characteristics:

1)Highly efficient thickeners/co-binders enabling excellent formulation

2)The preferred thickener for anhydrous formulation

3)Excellent mucoadhesive polymers, which protect and lubricate the mucosa as well as allow for prolonged active and flavor retention

4)Synergistic co-thickeners with either cellulosic polymers or natural gums

5)Optimal for providing enhanced aesthetics

6)Consistent from lot-to-lot due to their synthetic nature

7)Able to be processed by cold processing

9)Synthetic polymers with a lower bioburden that do not support microbial growth when compared to natural cellulosic polymers and gums

10)Compliant with global pharmacopeial requirements

Features:

1)Rheology modifiers

2)Binders

3)Suspension stabilizers

4)Mucoadhesive aids

2)The preferred thickener for anhydrous formulation

3)Excellent mucoadhesive polymers, which protect and lubricate the mucosa as well as allow for prolonged active and flavor retention

4)Synergistic co-thickeners with either cellulosic polymers or natural gums

5)Optimal for providing enhanced aesthetics

6)Consistent from lot-to-lot due to their synthetic nature

7)Able to be processed by cold processing

9)Synthetic polymers with a lower bioburden that do not support microbial growth when compared to natural cellulosic polymers and gums

10)Compliant with global pharmacopeial requirements

Features:

1)Rheology modifiers

2)Binders

3)Suspension stabilizers

4)Mucoadhesive aids

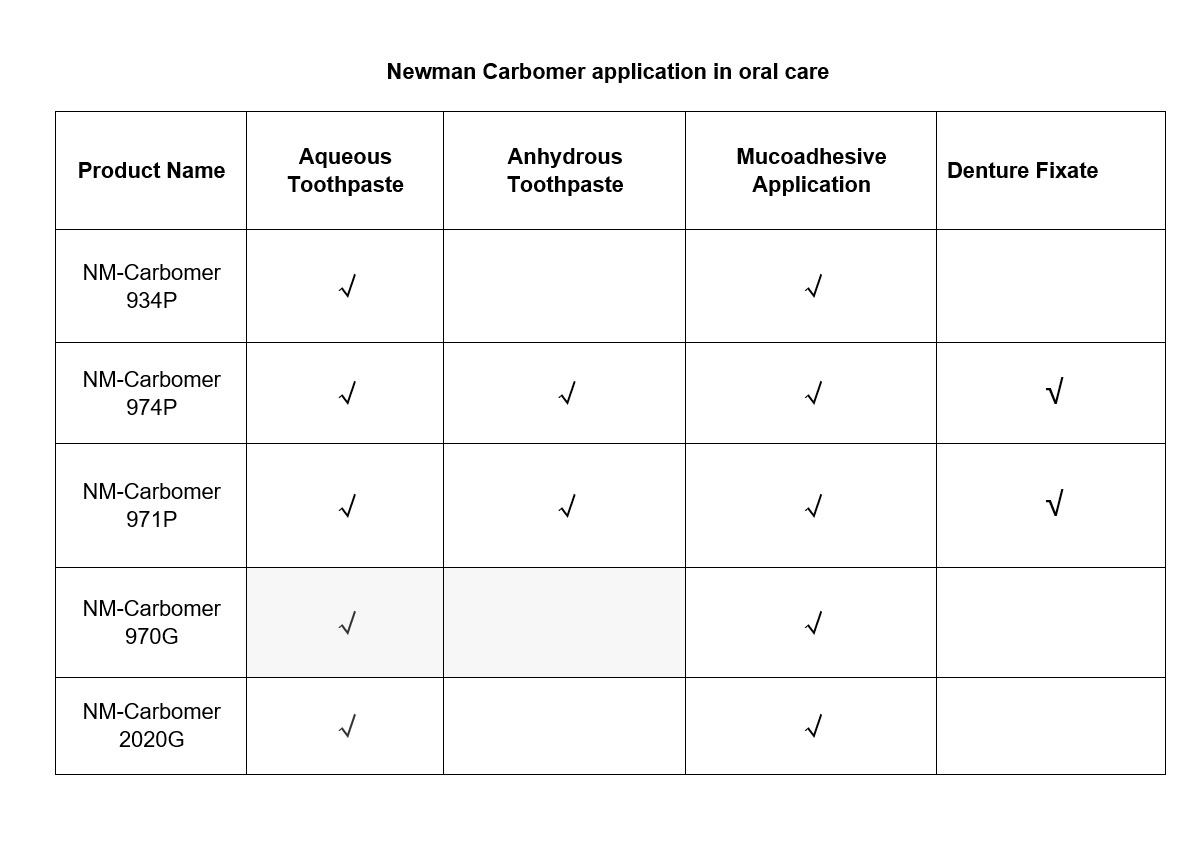

Tab1 NM-Carbomer products application in oral care.

Oral care related products

Topical Applications

Topical drug delivery offers a safe, more convenient treatment option for a variety of disorders when compared to systemic dosage forms.

Topical drug delivery can include dermal, nasal, ocular, rectal, and vaginal routes of administration. Liquid solutions and suspensions as well as semisolids such as creams, lotions, ointments, and gels are common topical drug delivery formats for a variety of indications.

Anhui Newman Fine Chemicals Co., LTd has extensive experience supplying best-in-class bioadhesive excipients that support topical drug products. Whether developing an over-the-counter product or prescription drug formulation, Anhui Newman is a comprehensive partner in the topical drug delivery space.

NM-Carbomer products have been used extensively in the development of safe and effective topical products. These excipients provide critical qualities to address market needs, including:

· Ideal Aesthetic and Sensory Qualities – increase patient compliance through low-irritation, aesthetically pleasing formulations with optimal feel

· Bioadhesion / Mucoadhesion – optimize drug delivery by prolonging product contact with biological membranes, improve patient compliance via reduced need for frequent drug administration, and protect and lubricate mucosal surfaces

· Efficient Rheology Modification and thickening for topical semisolids

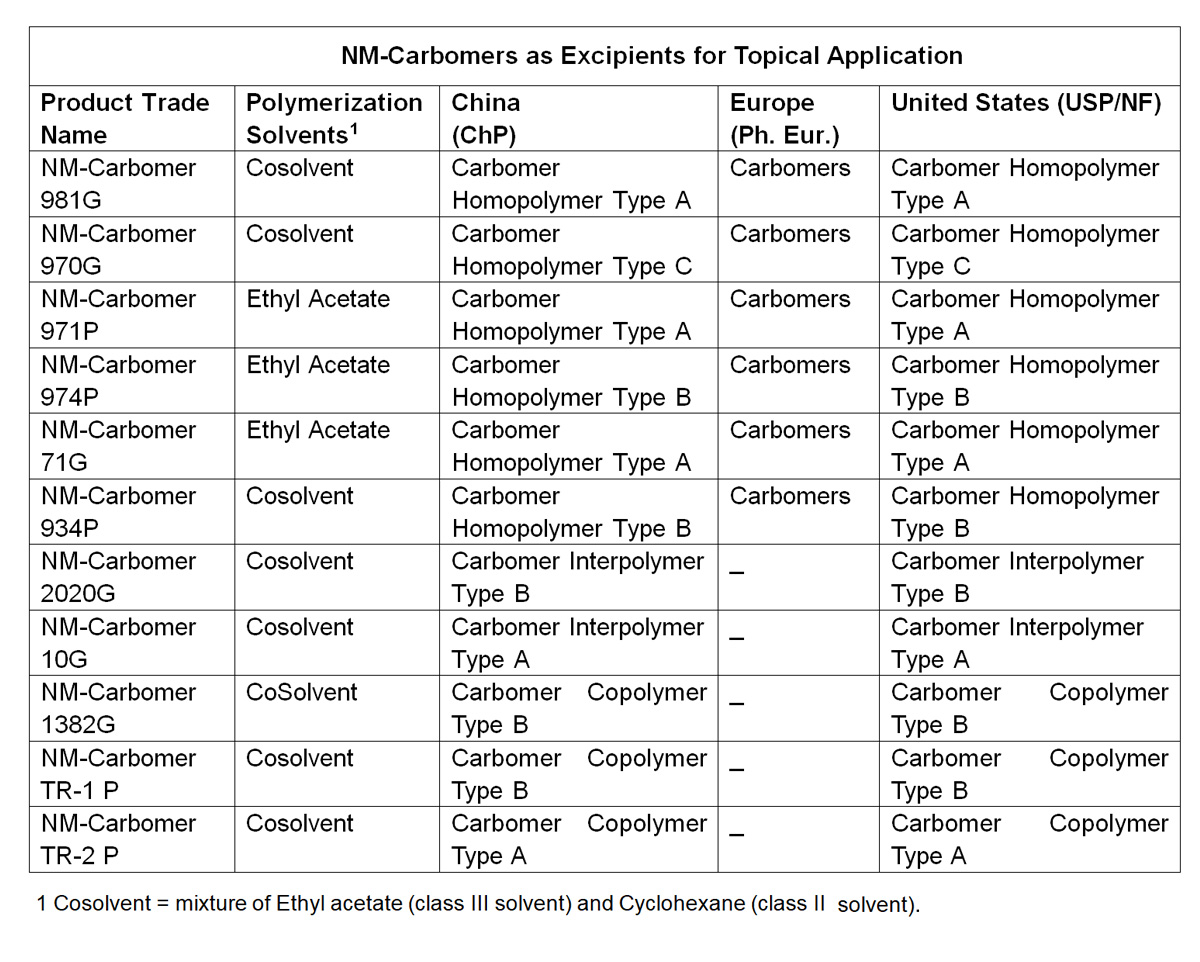

NM-Carbomers listed in the table below are suitable for use in topical applications and are present in commercialized topical products.

NM-Carbomer products have been used extensively in the development of safe and effective topical products. These excipients provide critical qualities to address market needs, including:

· Ideal Aesthetic and Sensory Qualities – increase patient compliance through low-irritation, aesthetically pleasing formulations with optimal feel

· Bioadhesion / Mucoadhesion – optimize drug delivery by prolonging product contact with biological membranes, improve patient compliance via reduced need for frequent drug administration, and protect and lubricate mucosal surfaces

· Efficient Rheology Modification and thickening for topical semisolids

NM-Carbomers listed in the table below are suitable for use in topical applications and are present in commercialized topical products.

Tab1 NM-Carbomer products application in oral care.

Topical Applications related products

Ophthalmic Applications

Topical drug delivery offers a safe, more convenient treatment option for a variety of disorders when compared to systemic dosage forms.

Delivery of therapeutics to the human eye is one of the most interesting, but challenging, endeavors a formulator can take on. Anhui Newman is well-equipped to meet your needs for ophthalmic formulation development, in both the anterior and posterior segments of the eye.

NM-Carbomer products are versatile and efficient in complex topical mucosal formulations. These monograph-compliant, mucoadhesive excipients are compatible with most active pharmaceutical ingredients (APIs) and provide essential properties for effective ocular formulation development, including:

· Bioadhesion / Mucoadhesion – maximize drug absorption by prolonging contact time with the eye, which can increase bioavailability, reduce dosing frequency, and subsequently improve patient compliance

· Versatility – compatible with a wide variety of acidic, basic, and neutral APIs across a broad pH range while providing customizable rheology and viscosity for your product

· Emulsification – ability to suspend oils in solution and suitable salt tolerance, which are important qualities for many topical products such as eye drops

· Non-irritating and non-toxic – enhances patient comfort and safety

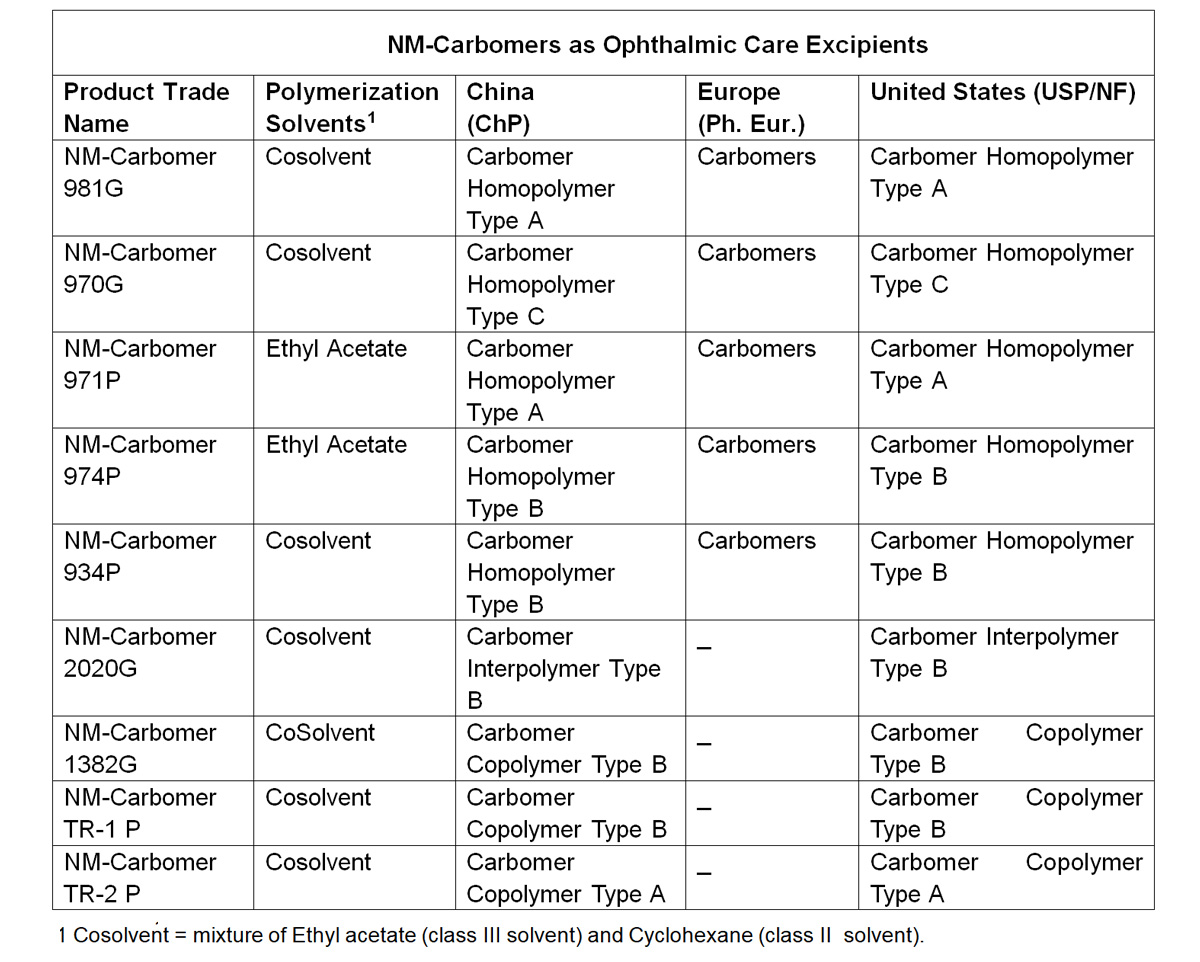

All polymers listed in the chart below are suitable for use in ocular applications and are present in ophthalmic commercialized products. Ocular applications can include solutions, suspensions, emulsions, and gels.

· Bioadhesion / Mucoadhesion – maximize drug absorption by prolonging contact time with the eye, which can increase bioavailability, reduce dosing frequency, and subsequently improve patient compliance

· Versatility – compatible with a wide variety of acidic, basic, and neutral APIs across a broad pH range while providing customizable rheology and viscosity for your product

· Emulsification – ability to suspend oils in solution and suitable salt tolerance, which are important qualities for many topical products such as eye drops

· Non-irritating and non-toxic – enhances patient comfort and safety

All polymers listed in the chart below are suitable for use in ocular applications and are present in ophthalmic commercialized products. Ocular applications can include solutions, suspensions, emulsions, and gels.

Ophthalmic Applications related products

Reference Information

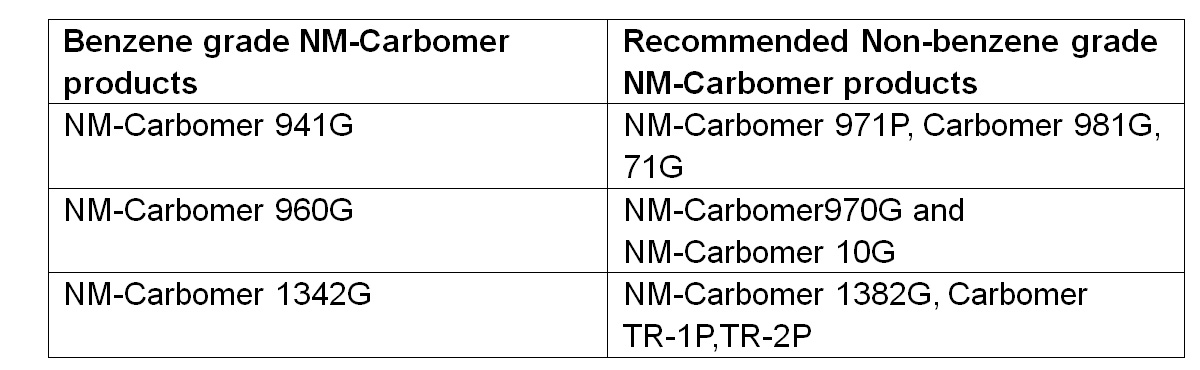

Anhui Newman continues to offer additional benzene-polymerized polymers not listed in the tables above.

Due to regulatory restrictions on the use of benzene in pharmaceutical formulations, Anhui Newman recommends that NM-Carbomers polymerized in either ethyl acetate or a cosolvent mixture of ethyl acetate and cyclohexane be used for all new drug development

Projects. Additionally, it may be desirable to substitute a benzene polymerized NM-Carbomer with a non-benzene polymerized NM-Carbomer in a pharmaceutical formulation. The following table shows recommended alternatives for the benzene-grade NM-Carbomer products based on viscosity criteria. If a substitution is made in a pharmaceutical formulation, it is recommended that key performance properties be ascertained, and regulatory considerations be taken into account. Depending on the desired dosage requirements, other NM-Carbomer products may be suitable alternatives.

Due to regulatory restrictions on the use of benzene in pharmaceutical formulations, Anhui Newman recommends that NM-Carbomers polymerized in either ethyl acetate or a cosolvent mixture of ethyl acetate and cyclohexane be used for all new drug development

Projects. Additionally, it may be desirable to substitute a benzene polymerized NM-Carbomer with a non-benzene polymerized NM-Carbomer in a pharmaceutical formulation. The following table shows recommended alternatives for the benzene-grade NM-Carbomer products based on viscosity criteria. If a substitution is made in a pharmaceutical formulation, it is recommended that key performance properties be ascertained, and regulatory considerations be taken into account. Depending on the desired dosage requirements, other NM-Carbomer products may be suitable alternatives.

Polyvinylpyrrolidone (PVP)

PVP are excellent film-forming capacity, adhesiveness and chemical stability, no toxicity. Povidone is one of the most important excipients for pharmaceutical industry:1) Binder for tables, capsule,2) Sugar coatings and films,3) Thickening agent,4) Solubility Improver for poorly soluble drugs,5)Bioavailability Enhancer for drug’s active ingredients,6)Pore-forming for membrane product

Polyvinylpyrrolidone (PVP) products